Non fried instant noodles processing line adopts advanced technology, high degree of automation, with reasonable layout and easy maintenance. The produced instant noodle is of high quality and good taste. This plant uses automatically temperature control, which ensures the original color of the noodle flavor and nutritional composition. Is ideal equipment for non-fried instant noodle production.

Non fried instant noodles processing line adopts advanced technology, high degree of automation, with reasonable layout and easy maintenance. The produced instant noodle is of high quality and good taste. This plant uses automatically temperature control, which ensures the original color of the noodle flavor and nutritional composition. Is ideal equipment for non-fried instant noodle production.

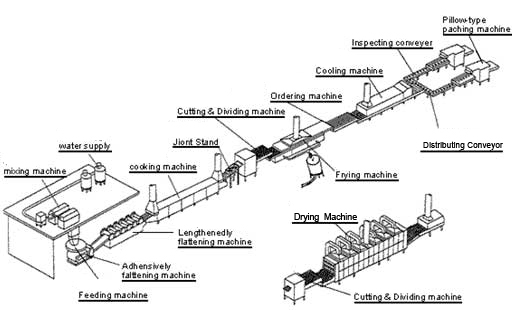

Production flow chart:

Flour mixing →Curing(about 20 minutes)→Composite continuous rolling→noodles steaming→ frame cutting→folding →drying→cooling → packing

| No. | Machine Name | Model | Quantity | Note |

| 1 | Brine quantifier and mixer | LG10 | 1 SET |

Power:0.75KW Volume:100L/SET |

| 2 | Double speed dough mixer | LG200 | 1 SET |

Power 9/11 kw, 200kg/pot/manual door opening |

| 3 | Disc cooker machine | LG200 | 1 SET |

Power:4kw Size of pan:Diameter1800mm*410mm |

| 4 | Composite and continuous dough pressing machine | LG7-50 | 1 SET |

Dough width 350mm power 5.5kw+5.5kw=11kw 7 sets steel roller |

| 5 | Single layer | LG50 | 1 SET |

16 meter, water sealing Main motor power 1.5kw Pan 0.37kw*2,stainless steel |

| 6 | Cutting,folding and conveying machine | LG80 | 1 SET |

Main power 1.5kw+0.75kw cutting blade 50 times/min |

| 7 | Double layers drying machine | LG50 | 1 SET |

Main motor power 1.5kw*2 (frequency control+fan 5.5kw*4,net width:2 meters, total length:30m) |

| 8 | Horizontal conveyor | LG63 | 1 SET | Main motor power 0.37kw |

| 9 | Cooling conveyor | LG63 | 1 SET |

One horizental:0.55kw, fan 0.37kw*4 length:6 meters.width:0.50 meter |

| 10 | Electricity control cabinet | LG-1 | 1 SET | Main program adopts frequency control, PLC program control |

| Total power |

About 55kw |

Leave Message